Panel and Plywood

Clennett’s supplies an exhaustive range of panel and plywood for your next job – plywood, bracing, marine ply, marine ply, particleboard, MDF and more.

Contact a Trade expert for more information, or request a quote.

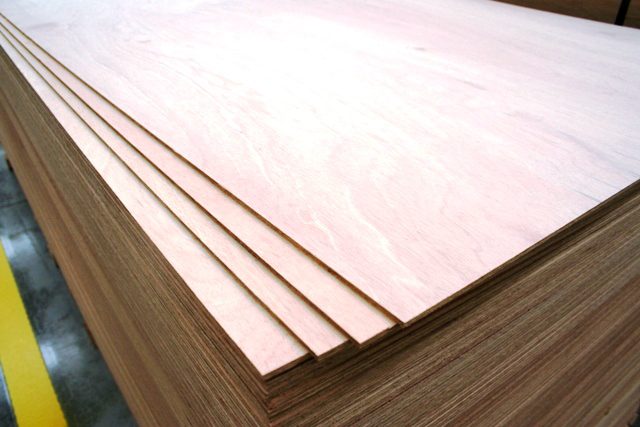

Structural Plywood (CD)

Structural plywood is an engineered wood panel designed to be a high-strength sheet for use in general structural building and construction, subject to an application’s load-bearing requirements.

Structural ply is commonly used as an untreated panel, but is also available in treated variants, typically H2-S, H2 or H3.

Whilst versatile in its use, structural plywood is manufactured first for its structural properties rather than aesthetics, and as such the face veneer may have some puttied splits and knotholes.

Non-Structural Plywood (CD)

Non-structural plywood is an economical plywood sheet for use in a broad range of applications from hoardings to furniture and wall linings.

Made with an A bond glue line to give it durability and performance. Non-structural ply is well suited to painting or staining.

Non-Structural ply is commonly used as an untreated panel, but can also be supplied in treated variants such as H2-S, H2 or H3 when required for long term outdoor use.

Whilst having some properties in common with structural plywood, non-structural ply is neither manufactured to nor tested against Australian Standards and carries no F rating. Therefore it is important that non-structural ply is only used in non-structural or non-load bearing applications.

Whilst versatile in its use, non-structural plywood is manufactured to be a low-cost plywood panel and as such the face veneer may have some puttied splits and knotholes.

Bracing Plywood

Hardwood Bracing Plywood (F22) is suitable for use in wall and roof bracing applications. Using bracing in timber-framed buildings affords designers the opportunity to incorporate large openings and areas of glass in external walls or additional wall strength for cyclonic areas.

Whilst only visible for a few weeks during the construction phase, bracing ply helps provides protection from wind damage for the life of the building.

Made from mixed-species hardwood sourced from legally harvested resources and an A Bond glueline to comply with AS2269. F22 Hardwood bracing plywood can be supplied in untreated and H2-S treated (i.e. against termites) variants.

It is important that all fixing of brace ply adhered to the Building Code of Australia and AS 1684 – Residential Timber Framed Construction Code.

Feature Ply (AC, BB, BC)

Sought for their decorative appearance qualities, feature grade hoop or radiata plys can be a stunning addition to any fit-out. Typically free of defects such as splits, large knots and putty the purity of the face veneer leaves a lasting impression.

Commonly finished in a clear to highlight the face, Feature Ply is ideal for use in a broad range of structural* and non-structural applications including decorative ceiling and wall linings, whether left solid, slotted or perforated with small holes.

An ideal decorative product for use in noise containment or attenuation applications.

If used externally or in applications exposed to moisture, it is recommended the panel is treated and sealed against fungal and termite attack with a recognised H3 treatment and finished with a paint or water repellent to minimise surface checking.

*When used as a structural product, care must be taken to comply with the relevant building and engineering codes based on the panel’s structural rating.

Bendy Ply

Branch out, you don’t always have to walk the straight line! Bendy Ply is a unique plywood sheet that has the ability to curve and bend around a very tight radius and bring to life your decorative ideas.

The versatility of Bendy Ply leads to it being widely used in a range of applications such as reception counters, columns and feature displays.

The high-grade face is cut in two directions to give you the option of long or short grain. Both are ideal for clear finishing or painting. Bendy ply is also suitable for overlaying with a natural timber veneer.

Bendy ply is interior non-structural plywood. It is not suitable for structural and wet area applications.

Lauan Ply

A decorative hardwood ply with earthy pink/brown tonings. Typically a subtle and consistent grain is a reliable choice when the appearance of the face is important. Easy to work with, paint or stain. Ideal for furniture and crafts.

Not suitable for structural applications or exterior use.

Lightweight Falcata

Being up to 38% lighter than standard hardwood plywoods, Falcata can deliver significant weight savings in an interior fit-out. Ideally suited for lightweight joinery applications such as laminated benchtops substrate and bench seats in caravans.

Falcata is typically of a lighter appearance than many traditional hardwood species with a clear face and a subtle grain.

Made with an interior moisture-proof bond to support longevity in use. Not suitable for structural applications or exterior use.

Safe and easier to handle, Falcata’s lightweight capabilities helps to address workplace fatigue for production and fit-out staff.

Polyester & Paper Overlaid Ply

Plywood with a decorative overlay that combines aesthetic appeal with easy routine cleaning and maintenance properties.

Available in a range of colours including White & Grey Embossed (polyester overlay) and Silver Cloud (paper overlay) with a matte or gloss finish. Minimum quantities and lead times apply to non-stocked colours. Please call your local branch for further information.

Routine cleaning simply involves wiping with a clean, damp soft cloth. Never use abrasive cleaners, scourer pads (eg: wire or copper cleaning pads) or sandpaper, or subject to excessive wetting.

Not recommended for use in wet areas or spaces with high relative humidity. Not suitable for structural applications or exterior use. It is recommended that panels are inspected for colour variation prior to installation.

Plywood Doorskins

Hardwood plywood Door Skins are commonly specified where high-quality faces are required, for example, decorative or commercial doors.

There is a choice of standard and premium skins when considering the look you want to achieve. The premium grade is typically suitable for clear finishing and the standard grade is ideally finished with a painted surface.

It is recommended that potential customers contact a representative from a Coating Company (Paint/Staining) in conjunction with an AWP Representative prior to specifying the coating applications for their Door Skins.

BB/CC Plywood

BB/CC hardwood ply is a very popular feature plywood choice for applications where the appearance of the face is important, but the back is less important. For example furniture, signs, movie sets, feature walls.

The faces have been sanded to make staining or painting easier, noting that as a natural product, colour variations will exist between sheets. The colour may range from a dark red to light blonde in appearance.

Manufactured using an ‘A’ bond resin, BB/CC is suitable for a range of applications involving some external exposure. It is recommended though that for applications involving long term full exposure, the panel is treated and sealed against fungal and termite attack with a recognised H3 treatment and finished with a paint or water repellent to minimise surface checking.

Whilst BB/CC is non-structural plywood, being manufactured from 100% hardwood, the product is quite naturally durable and strong.

The BB face may at times have small filled and sanded imperfections.

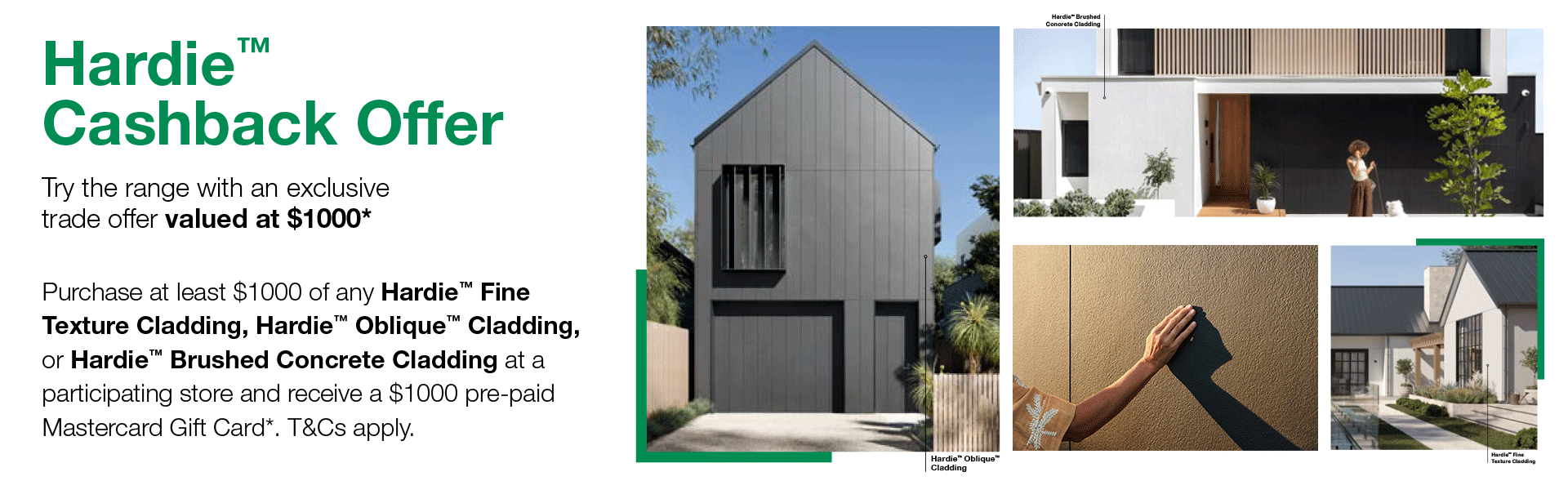

Plywood Cladding

SHADOWclad decorative structural plywood cladding is a stylish and versatile building product suitable for both outdoor and indoor building applications. Favoured by architects, designers and builders alike for its strength, durability and appearance, SHADOWclad allows you to achieve a beautiful façade without an expensive price tag.

SHADOWclad can be used in a broad range of external applications once sealed with a suitable paint or stain system and installed to recommended guidelines. It has been treated with LOSP (H3) to help protect the cladding from both insect (termite) and fungal (rot) attacks.

With the panels being lightweight in relation to other cladding options, it is ideally suited to projects constructed on sloping blocks. No special tools are required and with inherent bracing strength, SHADOWclad can eliminate the requirement for another bracing product in the construction process.

SHADOWclad is available in either primed (beige) or natural look with a textured or grooved finish and is manufactured from plantation pine timber, a renewable resource.

(SHADOWclad ® is a trademark of Carter Holt Harvey Wood products)

OSB Bracing (OS’Brace®)

OS’Brace® is a high quality, moisture-resistant structural bracing panel for timber-framed construction that resists splitting and delamination. OS’Brace® is simple to install – lightweight, easy to cut, nail, screw and drill. Can be nailed or stapled subject to manufacturer’s guideline.

OS’Brace® provides four simple bracing systems, offering up to 6 kN/m racking resistance when fixed to timber framing (JD5 minimum) in accordance with the manufacturer’s guidelines.

Manufactured by EGGER in Europe, OS’Brace® is constructed as a three-layered OSB panel of oriented strands (micro-veneers) bonded with a synthetic resin designed specifically for the Australian building and construction industry.

OS’Brace is available as either an Untreated or Treated (H2) panel. The H2 treated panel is suitable for use across Australia and is easily identified by a blue stamp.

(OS’Brace® is a trademark of EGGER Holzwerkstoffe Wismar GmbH & Co. KG)

OSB Panel

Economical, strong and sturdy non-structural wood-based panel suitable for a diverse range of applications. Ideal for packaging with high pull-out resistance of the fasteners, even along the edges.

Made from oriented strands (micro-veneers) bonded with synthetic resin.

Marine Ply (BS1088)

Utilising high-quality hardwood veneers, the Samling marine plywood is a superior plywood panel with negligible splits or knots produced in accordance with the international standard BS 1088.

Manufactured using an A-grade sanded face on both sides of the panel, Samling BS1088 marine ply is an ideal choice where surface decoration or appearance is a primary consideration.

BS 1088 marine plywood is produced with an A bond/ WBP glue line and untreated tropical hardwood veneers.

Whilst the A/WBP bond performs better in humid and wet conditions and resists delaminating if you intend to use the product externally or in applications exposed to prolonged moisture, it is recommended the panel is treated and sealed against fungal and termite attack with a recognised H3 treatment and finished with a paint or water repellent to minimise surface checking.

No marine species are naturally durable in water and preservative treatment of marine plywood used in exposed marine environments is a necessity.

Marine Ply (AS/NZS 2272-2006)

Manufactured using high-quality plantation hoop pine veneers and a type A Phenolic bond, hoop pine plywood is well suited to marine applications based on its density, bending strength, impact resistance and surface finishing characteristics.

Utilising high-grade hoop pine veneers both on the faces plus the core layers and certified to AS/NZS 2272-2006, hoop pine plywood is ideal for use in the hulls of boats, pontoons and other marine applications.

Based on its superior visual properties, hoop marine ply when finished in a high-quality clear polyurethane finish is also a very desirable product in a range of internal decorative applications such as ceiling linings, alfresco etc.

Please note that no marine species are naturally durable in water and preservative treatment of marine plywood used in exposed marine environments is a necessity.

Hoop marine plywood is typically not suitable for fully exposed applications (ie wall cladding) based on its propensity to check on the surface and the manufacturer’s recommendation to not use oil-based finishes.

Hardform Formply

Made from high-quality hardwood veneers with an A bond resin, Hardform formply is manufactured under a strict 3rd party quality control programme, designed to deliver a smooth finish whilst withstanding the normal rigours of concrete form working.

Durable and reusable, Hardform is made from cross-banded veneers and high-quality phenolic surfaces to provide users with the convenience of both bi-directional strength (F14 or F17) and dimensional stability.

Hardform is capable of achieving a class 2 finish on the first pour (per AS/NZ3610-2007) when used with appropriate installation expansion distances between sheets, release agents, tapes and solid perimeter fixings. (Class 2 finish – AS/NZ3610 -2007 mandates the need for a test pour to confirm finish where a Class 2 finish is specified).

Versatile and cost-effective, Hardform formply can be used in:

- Optimised form systems such as table forms and jump forms;

- Steel or timber form frame systems; and

- Across a range of frame spacings, slab thicknesses and surface tolerances (subject to the structural design requirements of AS/NZ3610 and the F rating of the panel)

Formply (Softwood)

Formply is a product that is durable, reusable and designed to produce a smooth off-form concrete finish.

Formply is capable of achieving a class 2 finish on the first pour (when used in accordance with Carter Holt Harvey’s installation details and AS 3610 recommendations).

Formply F17/14 * is manufactured utilising a plantation softwood core, a thin hardwood face and overlay combined with an “A” Bond phenolic adhesive and water repellent edge sealant to provide protection against typical construction moisture.

Formply F14 is a full softwood product (CCFO).

Engineered Wood Products Association of Australasia (EWPAA) ‘Product Certified’ against AS 6669-2007 for peace of mind.

Particleboard Raw

Particleboard is an engineered wood product that is manufactured from wood particles and synthetic resins. Typically produced in Australia from managed and renewable plantation pine, particleboard is available in a wide range of sheet sizes.

White Melamine Particleboard

White Melamine on a Particleboard substrate is a versatile interior panel commonly used in a range of shelving, furniture and joinery applications. Commonly white melamine particleboard is either overlaid with white decorative paper on both sides of the board or overlaid with white decorative paper and edged along one long side.

Particleboard Flooring

Particleboard flooring has been available in the Australian market for many years and has proven itself to be an economical and hard-wearing building material for residential and light commercial construction. Fast and easy to install. Particleboard Flooring is available in 3 different thicknesses, either as an untreated or termite-treated (H2) panel.

MDF Raw

MDF is a versatile and easy to use panel designed for general purpose interior use. Typically manufactured to be of uniform size, colour, density and strength, MDF makes an ideal substrate for numerous applications. Available in a diverse range of resin types, including low formaldehyde emission panels (SE0).

White Melamine MDF

White Melamine on an MDF substrate is a versatile interior panel commonly used in a range of shelving, furniture and joinery applications. Overlaid in the factory with hard-wearing melamine impregnated decorative white paper to both sides.

Contact a Trade expert for more information, or request a quote.